Our factory -Far east which specializes in doing R&D, production and sales of carbon fiber composite core conductor in 2006.

The reference standards of carbon fiber composite core conductor are ASTM B609, ASTM B857, ASTM B987 and other international advanced standard. The type of carbon fiber composite core conductor is JLRX1/F1B(ASTM) ( J-Over head conductor, LR-Full Annealed aluminum, X1-Trapezoidal Wire, F1B-carbon fiber composite core, ASTM-Reference standard of composite core is ASTM B987/B987M), which is represented by the nominal cross section of aluminum and composite core. Electric aluminum is full annealed aluminum, whose conductivity is more than 63% IACS and its cross section is designed to be trapezoidal-shape, which can reduce the outer diameter of conductor greatly.

Production Equipment and Testing Equipment for Carbon Fiber Composite Core Conductor

1. Production Equipment for Carbon Fiber Composite Core Conductor

Pultrusion Machine for Composite Core(China)

Plopez Continuous Casting and Rolling Production Line(Italy)

Aluminum Continuous Extruder (China)

JKL 710/12+18+24+30 Frame Strander (China)

2. Testing Equipment for Carbon Fiber Composite Core Conductor

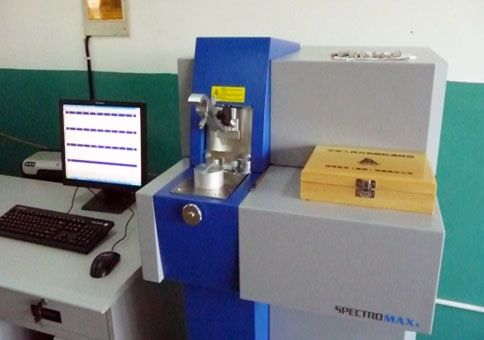

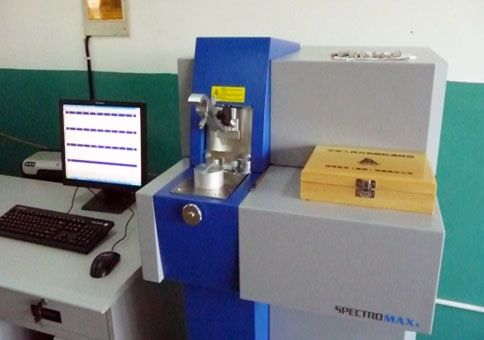

SPECTROMAXx-FV-M Spectroanalysis Instrument (Germany)

1000 kN Tensile Testing Machine (China)

CMT4104、CMT6504 Tensile Testing Machine (China)

Dynamic Thermal Mechanical Analyzer (DMA) (America)

Mandrel Coiling Tester (China)

Mandrel Torsion Tester (China)

Salt Spray Test Chamber (China)

Ultraviolet Aging Test Chamber (China)

Pultrusion Machine for Composite Core(China)

Pultrusion Machine for Composite Core(China)  Plopez Continuous Casting and Rolling Production Line(Italy)

Plopez Continuous Casting and Rolling Production Line(Italy)  Aluminum Continuous Extruder (China)

Aluminum Continuous Extruder (China)  JKL 710/12+18+24+30 Frame Strander (China)

JKL 710/12+18+24+30 Frame Strander (China)  SPECTROMAXx-FV-M Spectroanalysis Instrument (Germany)

SPECTROMAXx-FV-M Spectroanalysis Instrument (Germany)  1000 kN Tensile Testing Machine (China)

1000 kN Tensile Testing Machine (China)  CMT4104、CMT6504 Tensile Testing Machine (China)

CMT4104、CMT6504 Tensile Testing Machine (China)  Dynamic Thermal Mechanical Analyzer (DMA) (America)

Dynamic Thermal Mechanical Analyzer (DMA) (America)  Mandrel Coiling Tester (China)

Mandrel Coiling Tester (China)  Mandrel Torsion Tester (China)

Mandrel Torsion Tester (China)  Salt Spray Test Chamber (China)

Salt Spray Test Chamber (China)  Ultraviolet Aging Test Chamber (China)

Ultraviolet Aging Test Chamber (China)