1、电缆型号---Type of cable

1、电缆型号---Type of cable

型 号 Type | 名称 Description | 适 川 范 旧 Application |

YJV YJLV YJY YJLY

YJV62 YJLV62 YJV63 YJLV63 YJV22 YJLV22 YJV23 YJLV23 | 铜芯交联聚乙烯绝缘聚氯乙烯护套电力电缆 Copper conductor XLPE insulated PVC shealhed power cable 铝芯交联聚乙烯绝缘聚氯乙烯护瘀电力电缆 Aluminum conductor XLPEInsulated PVC sheathed power cable 铜芯交联聚乙烯绝缘聚乙烯护套电力电缆 Copper conductor XLPE insulated PE sheathed power cable 铝芯交联聚乙烯绝缘聚乙烯护套电力电缆 Aluminium conduclo XLPE insulated PE shealhed power cable. 钢芯交联聚乙烯绝缘非磁性金属带铠装聚氯乙烯护套电力电缆 Copper conductor XLPE insulated steel tape amoured PVC sheathed Power cable 铝芯交联聚乙烯绝缘非磁性金属带铠装聚氯乙烯护套电力电缆 Aluminum conductor XLPE insulated steel tape amoured PVC sheathed Power cable 铜芯交联聚乙烯绝缘非磁性金属带铠装聚乙烯护套电力电缆 Copper conduclor XLPE Insulated steel tape armoured PE shealhed Power cable 铝芯交联聚乙烯绝缘非磁性金属带铠装聚乙烯护套电力电缆 Aluminium conduclor XLPE insulated steel tape amoured PEsheathed Power cable 铜芯交联聚乙烯绝缘钢带铠装聚氯乙烊护套电力电缆 Copper conduclor XLPE insulated steel tape amoured PVC sheathed power cable 铝芯交联聚乙烯绝缘锅带铠装聚额乙烯护套电力电缆 Aluminum conductor XLPE insulated steel tape amoured PVC sheathed power cable 铜芯交联聚乙烯绝缘锅带铠装聚乙烯护套电力电统 Copper conductor XLPE insulated steel tape amoured PE sheathed power cable 铝芯交联聚乙烯绝缘钢带铠装聚乙烯护套电力电缆 Aluminium conductor XLPE insulated steel tape armoured PE sheathed power cable | 室内、游道及电缆沟等不能承 受机械外力的场所。单芯电缆 不允许致设在磁性管道中。 For laying in doors、in lunnels and direct in ground,unable to bear external mechanical forces.Single core cable ln magnetic ducl is not permissible

室内、隧道、电缆沟等能承受 机枝外力的场所,但不能承受 大的拉力= For laying in doors、in tunnels and direct in ground,able to bear external mechanica forces,but unable to bear large puling force.

室内、隧道、电缆沟、竖井等 能承受机械外力和一定拉力的 场所。 For laying in doors,in tunnels and direcl In ground and wells,able to bear externa rmechanical forces and certain pulling force.

室内、隧道、电缆沟、竖并等 能承受机械外力和较大拉力的 场所。 For laying in doorsin tunnels and direct in ground and wells.able to bear external mechanical forces and large pulling force. |

YJV72 铜芯交联聚乙烯绝缘非磁性金属丝铠装聚氮乙烯护套电力电统 Cooper core,XLPE insulated,non magnetic,metal wire armored,PVC sheathed power cable YJLV72 铝芯交联聚乙烯绝缘非磁性金属丝铠装聚氧乙烯护套电力电缆 Aluminum core,XLPE insulated,non magnetc,metal wre armored,PVC shealhed power cable YJV73 铜芯交联聚乙烯绝缘非磁性金属丝铠装聚乙烯护套电力电统 Cooper core,XLPE insulated,non magnetic,melal wire amored,PE shealhed power cable YJLV73 铝芯交联聚乙烯绝缘非磁性金属丝铠装聚乙烯护套电力电缆 Aluminum core,XLPE Insulated,non magnetic,metal wire armored,PE sheathed power cable YJV32 铜芯交联聚乙烯绝缘细钢丝铠装聚氢乙烯护套电力电缆 Copper conductor XLPE insulated fine steel wire amoured PVC sheathed power cablo YJLV32 铝芯交联聚乙烯绝缘细钢丝铠装聚氮乙烯护套电力电缆 Aluminium conductor XLPE insulated fine sleel wire amoured PVC sheathed power cable YJV33 铜芯交联聚乙烯绝缘细钢丝铠装聚乙烯护套电力电统 Copper conductor XIPE insulated fine steel wire armoured PE sheathed power cable YJLV33 铝芯交联聚乙烙绝缘细钢丝铠装聚乙烯护套电力电缆 Aluminium conductor XLPE Insulated fine steel wre amoured PE shealhed power cable YJV42 铜芯交联聚乙烯绝缘粗钢丝铠装聚氯乙烯护套电力电缆 Copper core XLPE insulated steel wire amoured PVC sheathed power cable. YJLV42 铝芯交联聚乙烯绝缘粗钢丝铠装聚乙烯护套电力电缆 Aluminlum core XLPE insuated steel wre armoured PVC sheathed power cable YJV43 铜芯交联聚乙烯绝缘粗钢丝铠装聚乙烯护套电力电缆 Copper core XLPE insulaled steel wre armoured PE sheathed power cable YJLV43 铝芯交联聚乙烯绝缘粗钢丝铠装聚乙烯护套电力电缆 Aluminium core XLPE insulated steel wire amoured PE sheathed power cable |

|

四、电缆额定电压的选择---Voltage designation

电缆额定电压应适合于电缆的系统的运行状况,用U₀/U(Um)表示,均为有效值,单位为kV。

The rated voltages of the cables are applied to the system voltages and running state,and expressed in the form U₀/U.Where:

● U₀—电缆设计用导体与屏蔽或金属套之间的额定工作电压;

Uo—The rated power-frequency voltage between conductor and earth,for which the cable design.

●U—电缆设计用导体之间的额定工频电压;

U—The rated power-frequency voltage between conductors for which the cable design.

●Um—使用电缆的电力系统最高电压的最大值。

Um—The maximum sustained power frequency voltage between conductors for which the cable is

suitable.

◎三相系统用电缆的额定电压如下表规定:

Rated voltages of cable are given in table

U | Um | A,B类电电缆 A,B.class | C类电缆 C class |

6 | 7.2 | 3.6 | 6 |

10 | 12 | 6 | 8.7 |

15 | 17.5 | 8.7 | 12 |

20 | 24 | 12 | 18 |

30 | 36 | 18 |

|

35 | 40.5 | 21 | 26 |

注:A类一该类系统任一相导体与地或接地导体接触时,能在1min内与系统分离;

A category -when any phase conductor of this system is connected wlth the ground or earthing conductor,it will be separated from the system within 1 min.

B类一该类系统可在单相接地故障时短时运行,接地故障时间按照JB/T8996-1999应不超过1h。对于本部分包括的电缆,在任 何情况下允许不超过8h的更长的带故障运行时间。任何一年接地故障的总持续时间应不超过125h;

B category -this system will perate within a short time during the period of single phase-lo-earth fault.The earth fau e will not exceed 1h according toJB/T8996-1999.For the cable of this system,the max fault operating time shall ot exceeds he total time of earth fault shall not exceed 125h in one year.

C类一包括不属于A类、B类的所有系统。

C category-including any other system that does not belong toA category and B category.

四 、 电 缆 额 定 电 压 的 选 择 - - - V o l t a g e d e s i g n a t i o n

◎ 电 缆 额 定 电 压 应 适 合 于 电 缆 的 系 统 的 运 行 状 况 , 用 U₀/ U ( U m ) 表 示 , 均 为 有 效 值 , 单 位 为 K V 。

The rated voltages of the cables are applied to the system voltages and running state,and expressed in the form U₀/U.Where:

● U o — 电 缆 设 计 用 导 体 与 屏 蔽 或 金 属 套 之 间 的 额 定 工 作 电 压 ;

Uo—The rated power-frequency voltage between conductor and earth,for which the cable design.

● U — 电缆设计用导体之间的额定工频电压;

U—The rated power-frequency voltage between conductors for which the cable design.

● U m — 使 用 电 缆 的 电 力 系 统 最 高 电 压 的 最 大 值 。

Um—The maximum sustained power frequency voltage between conductors for which the cable is

suitable.

⑥ 三相系统用电缆的额定电压如下表规定:

Rated voltages of cable are given in table

|

| Uo |

|

U | Um | A,B类电缆 A,B class | C类电缆 C class |

6 | 7.2 | 3.6 | 6 |

10 | 12 | 6 | 8.7 |

15 | 17.5 | 8.7 | 12 |

20 | 24 | 12 | 18 |

30 | 36 | 18 | — |

35 | 40.5 | 21 | 26 |

注:A类一该类系统任一相导体与地或接地导体接触时,能在1min内与系统分离;

A category -when any phase conductor of this system is connected with the ground or earthing conductor,it will be separated from the system within 1 min.

B类一该类系统可在单相接地故障时短时运行,接地故障时间按照JB/T8996-1999应不超过1h。对于本部分包括的电缆,在任 何情况下允许不超过8h的更长的带故障运行时间。任何一年接地故障的总持续时间应不超过125h;

B category -this system will operate within a short time during the period of single phase-to-earth fault.The earth fault time willnot exceed 1h according toJB/T8996-1999.For the cable of this system,the max fault operating time shall not exceed 8h.The total time of earth fault shallnot exceed 125h in one year.

C类一包括不属于A类、B类的所有系统。

C category-including any other system that does not belong to A category and B category.

六生产范围---Production Range of cable

型 号 Type

YJV YJLV YJY YJLY

YJV62 YJLV62 YJV63 YJLV63 YJV22 YJLV22 YJV23 YJLV23

YJV72 YJLV72 YJV73 YJLV73 YJV32 YJLV32 YJV33 YJLV33

YJV72

YJLV72

YJV73

YJLV73

YJV42

YJLV42

YJV43

YJLV43

芯 数 Cores

1

3

1

3

1

3

1

3

3.6/6

25-800

25-630

25-800

25-630

25-800

25-630

25-800

25-630

额 定 Rated

6/6 8.7/10

6/10 8.7/15

标称截面Nominal cro s

25-800 25-630

25-800

25-630

25-800

25-630

25-800

25-630 | 25-800 25-500

25-800

25-500

25-800

25-400

25-800

25-400 |

电 压 ( k V ) voltage

12/15 12/20

sectional

35-1600

35-630

35-1600

35-500

35-1600

35-400

35-1600

35-400

18/20 18/30

of areas(mm²)

50-1600

50-630

50-1600

50-500

50-1600

50-300

50-1600

50-400

21/35

50-1600

50-630

50-1600

50-500

50-1600

50-240

50-1600

50-300

26/35

50-1600

50-630

50-1600

50-500

50-1600

50-240

50-1600

50-300

注:单芯铠装电缆仅用于直流系统,若用于交流系统,应采用非磁性材料的铠装层或采用隔磁措施。

The single core amoured cables areused for D.C.system ony.AsforAC.system,the magneic isolation should be apliedin the steel armoure wires or non-magnetica materials should be used.

七、电缆结构尺寸---Construction

3 . 6/6kV单芯交联聚乙烯绝缘聚氯乙烯护套电力电缆 . (YJ V Y J LV) 3.6/6kV1 Core XLPE Insulated PVC Sheathed Power Cable.

标 称

俄 面

minal cross sectional

areas

mm²

35

50

70

95

120

150

185

导 体 直 径

Diameter of

conductor

mm

7.0 8.3 9.8 11.5 13.0 14.5 16.1

绝 缘 厚 度

Insulation thickness

mm

2.5 2.5 2.5 2.5 2.5 2.5 2.5

外 护 套 厚 度

Outer sheath Thickness

mm 1.8 1.8 1.8 1.8 1.8 1.8 1.9

电 缆 近 似 外 径

Approx.overall Diameter

mm 17.9 19.2 20.6 22.3 24.0 25.5 27.3

电缆近似重量

Cable approx.weight

kg/km

YJV 592 736 944 1216 1476 1754 2120

| YJLV 378 446 527 634 742 848 993 |

续表

标 称 截 面

Nominal cross

sectional

areas

mm2

240

300

400

500

630

导 休 直 径

Diameter of

conductor

mm

18.4 20.6 23.5 26.5 30.0

绝 缘 厚 度

Insulation thickness

mm

2.6 2.8 3.0 3.2 3.2

外护套 厚 度

Outer sheath Thickness

mm

1.9 2.0 2.1 2.2 2.3

电 缆 近 似外径

Approx.overall Diameter

mm

29.6 32.0 35.5 38.7 42.3

电缆近似重量

Cable approx.weight

kg/km

YJV 2696 3328 4152 5251 6647 | YJLV 1197 1420 1761 2144 2629 |

◎ 3 . 6/6KV三芯交联聚乙烯绝缘聚氯乙烯护套电力电缆 . (YJ V Y J LV) 3.6/6kV3 Cores XLPE Insulated PVC Sheathed Power Cable.

标 称 导 体 绝 缘 外 护 套 电 缆 近 电 缆 近 似 重 量

截 面 直 径 厚 度 厚 度 似 外 径 Cable approx.weight

Nominal cross Diameter Insulation Outer sheath Approx.overall kg/km

areas conductor

YJV YJLV

mm² mm mm mm mm

35 7.0 2.5 2.2 35.8 1880 1228

50 8.3 2.5 2.3 39.5 2373 1492

70 9.8 2.5 2.4 42.0 3020 1749

95 11.5 2.5 2.5 45.9 3900 2129

120 13.0 2.5 2.6 49.3 4720 2488

150 14.5 2.5 2.7 52.8 5631 2872

185 16.1 2.5 2.8 56.4 6781 3348

240 18.4 2.6 3.0 61.7 8592 4090

300 20.6 2.8 3.2 66.8 10518 4861

400 23.5 3.0 3.4 74.1 13309 6029

500 26.5 3.2 3.6 80.9 16644 7340

◎

3 . 6/6KV单芯交联聚乙烯绝缘非磁性金属带铠装聚氯乙烯护套电力电缆 . (YJ V62 YJ LV62) 3.6/6kV1 Core XLPE Insulated Steel Tape Armoured PVC Sheathed Power Cable

标 称 截 面

| 导 体 | 绝 缘 | 外护套 | 电缆近 | 电缆近似重量 |

直 径 | 厚 度 | 厚 度 | 似外径 | Cable | approx.weight |

Nominal cross sectional | Diameter of | Insulation thickness | Outer sheath Thickness | Approx.overall Diameter |

| kg/km |

areas | conductor |

|

|

| YJV62 | YJLV62 |

mm² | mm | mm | mm | mm |

|

|

35 50 70 | 7.0 8.3 9.8 | 2.5 2.5 2.5 | 1.8 1.8 1.8 | 21.2 22.3 23 | 818 957 1170 | 603 668 753 |

95 | 11.5 | 2.5 | 1.8 | 25.3 | 1470 | 888 |

120 | 13.0 | 2.5 | 1.8 | 26.8 | 1737 | 1004 |

150 | 14.5 | 2.5 | 1.9 | 28.4 | 2042 | 1135 |

185 | 16.1 | 2.5 | 1.9 | 30.1 | 2422 | 1295 |

240 | 18.4 | 2.6 | 2.0 | 32.6 | 3014 | 1536 |

300 | 20.6 | 2.8 | 2.1 | 36.2 | 3967 | 2109 |

400 | 23.5 | 3.0 | 2.2 | 39.7 | 4909 | 2518 |

500 | 26.5 | 3.2 | 2.3 | 43.0 | 6038 | 2983 |

630 | 30.0 | 3.2 | 2.5 | 46.9 | 7501 | 3562 |

Pultrusion Machine for Composite Core(China)

Pultrusion Machine for Composite Core(China)  Plopez Continuous Casting and Rolling Production Line(Italy)

Plopez Continuous Casting and Rolling Production Line(Italy)  Aluminum Continuous Extruder (China)

Aluminum Continuous Extruder (China)  JKL 710/12+18+24+30 Frame Strander (China)

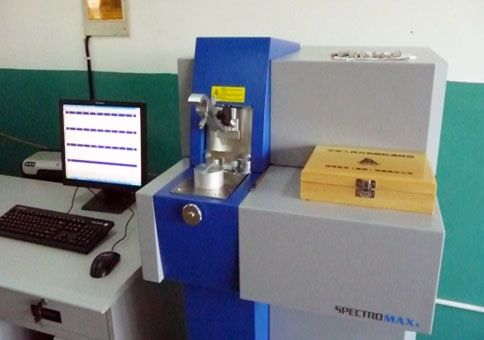

JKL 710/12+18+24+30 Frame Strander (China)  SPECTROMAXx-FV-M Spectroanalysis Instrument (Germany)

SPECTROMAXx-FV-M Spectroanalysis Instrument (Germany)  1000 kN Tensile Testing Machine (China)

1000 kN Tensile Testing Machine (China)  CMT4104、CMT6504 Tensile Testing Machine (China)

CMT4104、CMT6504 Tensile Testing Machine (China)  Dynamic Thermal Mechanical Analyzer (DMA) (America)

Dynamic Thermal Mechanical Analyzer (DMA) (America)  Mandrel Coiling Tester (China)

Mandrel Coiling Tester (China)  Mandrel Torsion Tester (China)

Mandrel Torsion Tester (China)  Salt Spray Test Chamber (China)

Salt Spray Test Chamber (China)  Ultraviolet Aging Test Chamber (China)

Ultraviolet Aging Test Chamber (China)