ROHS, UL, CUL,CSA APPROVAL...

CE(Conformité Européenne): Suitable for cables entering the European market, ensuring compliance with safety, health and environmental protection requirements.

TÜV certification

TÜV 2PfG 1169 and TÜV 2PfG 1990: German TÜV certification is widely used in Europe to test the key characteristics of photovoltaic cables such as weather resistance, UV resistance, flame retardancy, and insulation performance. Photovoltaic cables that meet TÜV certification can be used for a long time in harsh outdoor environments.

UL certification

UL 4703: A photovoltaic cable standard commonly used in North America, requiring cables to have high heat resistance, weather resistance, and high flame retardancy. Photovoltaic cables that have passed UL certification are widely used in the North American market and are suitable for grid-connected and off-grid photovoltaic systems.

EN certification

EN 50618: This is the photovoltaic cable standard for the European market, which stipulates the heat resistance, weather resistance, low smoke and halogen-free characteristics of photovoltaic cables. Cables that meet EN 50618 are usually used for photovoltaic installations in the EU market.

IEC Certification

IEC 62930: The global standard for photovoltaic cables issued by the International Electrotechnical Commission (IEC), covering characteristics such as high temperature resistance, UV resistance, low smoke and halogen-free. IEC 62930 certification is applicable to the global market, ensuring that photovoltaic cables meet the safety requirements of international power systems.

ISO 9001 and ISO 14001

These standard certifications guarantee the production quality management and environmental management of photovoltaic cables. ISO 9001 certification ensures that the factory's production process quality control meets international standards, while ISO 14001 focuses on environmental management.

RoHS Certification

Photovoltaic cables that meet RoHS (Restriction of Hazardous Substances Directive) certification do not contain harmful substances such as lead and cadmium, and are environmentally friendly.

VDE Certification (Germany)

VDE (German Association of Electrical Engineers) certification is used to evaluate the temperature resistance and anti-aging performance of cables, ensuring the stability and safety of cables in long-term outdoor applications.

Pultrusion Machine for Composite Core(China)

Pultrusion Machine for Composite Core(China)  Plopez Continuous Casting and Rolling Production Line(Italy)

Plopez Continuous Casting and Rolling Production Line(Italy)  Aluminum Continuous Extruder (China)

Aluminum Continuous Extruder (China)  JKL 710/12+18+24+30 Frame Strander (China)

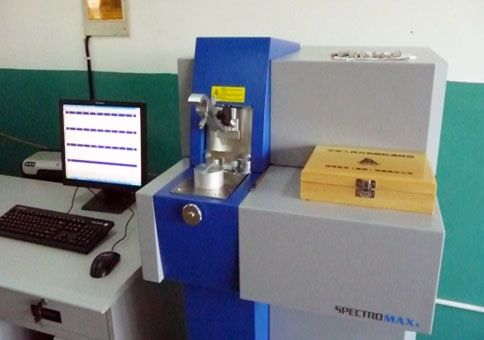

JKL 710/12+18+24+30 Frame Strander (China)  SPECTROMAXx-FV-M Spectroanalysis Instrument (Germany)

SPECTROMAXx-FV-M Spectroanalysis Instrument (Germany)  1000 kN Tensile Testing Machine (China)

1000 kN Tensile Testing Machine (China)  CMT4104、CMT6504 Tensile Testing Machine (China)

CMT4104、CMT6504 Tensile Testing Machine (China)  Dynamic Thermal Mechanical Analyzer (DMA) (America)

Dynamic Thermal Mechanical Analyzer (DMA) (America)  Mandrel Coiling Tester (China)

Mandrel Coiling Tester (China)  Mandrel Torsion Tester (China)

Mandrel Torsion Tester (China)  Salt Spray Test Chamber (China)

Salt Spray Test Chamber (China)  Ultraviolet Aging Test Chamber (China)

Ultraviolet Aging Test Chamber (China)