Power supply for lifting equipment

Crane cables are widely used in various lifting equipment, such as bridge cranes, gantry cranes, etc., to provide power supply for crane motors and control systems. Its highly flexible design ensures that the cable can smoothly transmit power when the crane moves, adapting to the frequent movement of equipment.

Port and terminal equipment

In ports and terminals, crane cables are used to power large machinery such as stackers and loading and unloading equipment. The wear resistance and tensile strength of the cable enable it to adapt to high-intensity mechanical movement and harsh working environments.

Automated production lines

Crane cables are widely used to power moving equipment in automated production lines, including robots, automatic conveying equipment, etc. They need to maintain the stability of power transmission during multi-axis and multi-directional movement, and avoid damage due to frequent bending.

Mines and mining equipment

In mining operations, driving cables are often used in mining equipment and transportation systems to help equipment continue to work in harsh environments. Its oil-resistant and corrosion-resistant properties allow the cables to work normally in high-oil and corrosive media in mining areas.

Large-scale storage systems

In large-scale storage and logistics systems, driving cables are used to connect automated cargo stackers, automated guided vehicles and other equipment to ensure that the power supply is not interrupted during frequent movement of equipment.

High-altitude cable transmission

Driving cables can also be used in high-altitude cable transmission systems, such as for powering cranes at high-rise construction sites. Its tensile and weather-resistant properties enable it to work safely and stably during high-altitude operations.

Pultrusion Machine for Composite Core(China)

Pultrusion Machine for Composite Core(China)  Plopez Continuous Casting and Rolling Production Line(Italy)

Plopez Continuous Casting and Rolling Production Line(Italy)  Aluminum Continuous Extruder (China)

Aluminum Continuous Extruder (China)  JKL 710/12+18+24+30 Frame Strander (China)

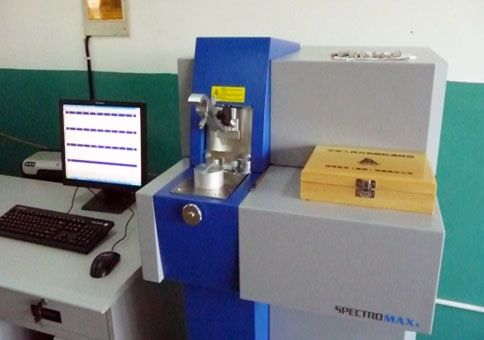

JKL 710/12+18+24+30 Frame Strander (China)  SPECTROMAXx-FV-M Spectroanalysis Instrument (Germany)

SPECTROMAXx-FV-M Spectroanalysis Instrument (Germany)  1000 kN Tensile Testing Machine (China)

1000 kN Tensile Testing Machine (China)  CMT4104、CMT6504 Tensile Testing Machine (China)

CMT4104、CMT6504 Tensile Testing Machine (China)  Dynamic Thermal Mechanical Analyzer (DMA) (America)

Dynamic Thermal Mechanical Analyzer (DMA) (America)  Mandrel Coiling Tester (China)

Mandrel Coiling Tester (China)  Mandrel Torsion Tester (China)

Mandrel Torsion Tester (China)  Salt Spray Test Chamber (China)

Salt Spray Test Chamber (China)  Ultraviolet Aging Test Chamber (China)

Ultraviolet Aging Test Chamber (China)