Highly Flexible Design for Dynamic Environments

Our flat cables are engineered for exceptional flexibility, making them ideal for dynamic applications that involve frequent bending and movement. They are perfect for use in automated production lines, robotic arms, elevators, and similar equipment, ensuring seamless and reliable operation even in demanding environments.

Company Advantage: Our advanced manufacturing equipment ensures that these cables maintain top performance even under high-flexibility conditions.

Space-Efficient Design for Compact Installations

The flat design of these cables maximizes space utilization, making them a perfect solution for applications with limited installation space, such as control cabinets and mechanical equipment.

Company Advantage: We offer customizable size solutions, ensuring that the cables fit perfectly into your specific equipment requirements, providing customers with unparalleled flexibility.

Superior Heat Dissipation, Safe and Reliable

Thanks to their large surface area, our flat cables facilitate excellent heat dissipation. This ensures they operate safely and do not overheat during prolonged high-load usage, promoting equipment reliability.

Company Advantage: Through rigorous quality control and advanced technology, we guarantee exceptional stability and durability of our cables in various industrial conditions.

Vibration-Resistant Design, Suitable for Harsh Environments

The flat structure helps to disperse vibration stresses, making these cables suitable for rugged environments such as railways, ships, and mines.

Company Advantage: We use wear-resistant and pressure-resistant materials, ensuring durability and minimizing maintenance needs in complex environments.

High and Low-Temperature Resistance for Extreme Conditions

Our flat cables maintain stable performance even in extreme temperatures, making them ideal for specialized environments like high-temperature workshops or cold storage.

Company Advantage: Our products undergo extensive temperature testing and meet international certification standards to deliver reliable electrical solutions in extreme climates.

Corrosion and Chemical Resistance

The corrosion-resistant outer materials of our flat cables make them well-suited for corrosive environments, such as chemical plants and the oil and gas industries.

Company Advantage: With extensive experience in serving the chemical and energy industries, we offer the best materials and solutions tailored to different environmental challenges.

Low Smoke Halogen-Free Materials, Safe and Environmentally Friendly

Our flat cables are manufactured from low smoke halogen-free materials, which prevent the release of toxic gases in case of fire, ensuring safety for both the environment and personnel.

Company Advantage: Committed to environmental protection and sustainability, all our products adhere to international environmental standards, providing customers with safe, eco-friendly options.

Multi-Conductor Configuration for Stable Signal Transmission

With their multi-conductor design, our flat cables support stable and interference-free signal transmission, making them ideal for automation control and precision equipment.

Company Advantage: We offer flexible customization services, allowing customers to configure the number and specifications of conductors to ensure optimal signal quality across various applications.

Tailored Solutions to Meet Specific Needs

Our flat cables support extensive customization, including conductor count, insulation materials, and sheath types, making them suitable for a wide range of complex applications.

Company Advantage: With years of experience and a professional technical team, we offer comprehensive custom solutions, providing expert guidance from the initial design phase to final delivery.

Pultrusion Machine for Composite Core(China)

Pultrusion Machine for Composite Core(China)  Plopez Continuous Casting and Rolling Production Line(Italy)

Plopez Continuous Casting and Rolling Production Line(Italy)  Aluminum Continuous Extruder (China)

Aluminum Continuous Extruder (China)  JKL 710/12+18+24+30 Frame Strander (China)

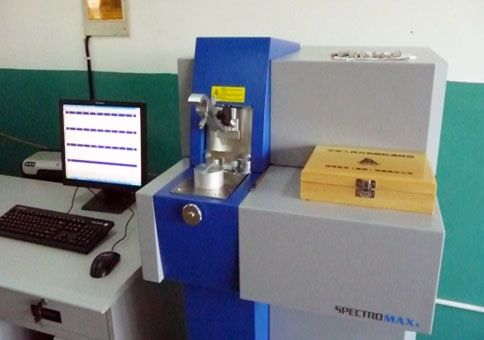

JKL 710/12+18+24+30 Frame Strander (China)  SPECTROMAXx-FV-M Spectroanalysis Instrument (Germany)

SPECTROMAXx-FV-M Spectroanalysis Instrument (Germany)  1000 kN Tensile Testing Machine (China)

1000 kN Tensile Testing Machine (China)  CMT4104、CMT6504 Tensile Testing Machine (China)

CMT4104、CMT6504 Tensile Testing Machine (China)  Dynamic Thermal Mechanical Analyzer (DMA) (America)

Dynamic Thermal Mechanical Analyzer (DMA) (America)  Mandrel Coiling Tester (China)

Mandrel Coiling Tester (China)  Mandrel Torsion Tester (China)

Mandrel Torsion Tester (China)  Salt Spray Test Chamber (China)

Salt Spray Test Chamber (China)  Ultraviolet Aging Test Chamber (China)

Ultraviolet Aging Test Chamber (China)