Introduction

In the power and energy industry, efficient signal transmission and reliable connectivity are essential. Cables form the backbone of industrial systems, linking power sources, control panels, automation devices, and safety systems. Among the most widely discussed options are control cables and hybrid cables. While both play critical roles, they serve different purposes.

This article explores how hybrid cables differ from control cables, their applications in the energy sector, and how decision-makers can select the right type for their projects.

Hybrid Cables vs. Control Cables: Core Differences

When discussing control cable applications, it is crucial to contrast them with hybrid cables. Both cable types may appear similar in construction, yet their functions and design priorities diverge significantly.

Function and Purpose

Control cables are primarily designed for signal transmission and control operations within automation systems, substations, or industrial machinery. Their main job is to send instructions rather than carry power. Hybrid cables, on the other hand, combine multiple functions into a single sheath—often merging power conductors with fiber optics or signal lines. This integration allows them to handle both energy transmission and data communication simultaneously.

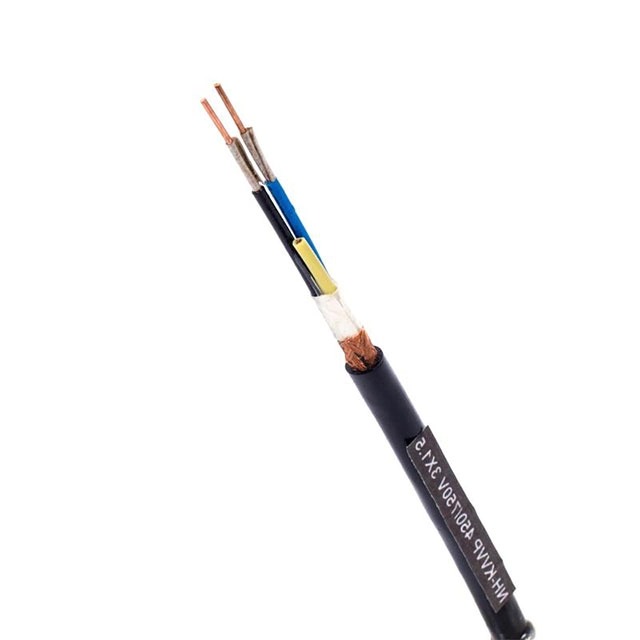

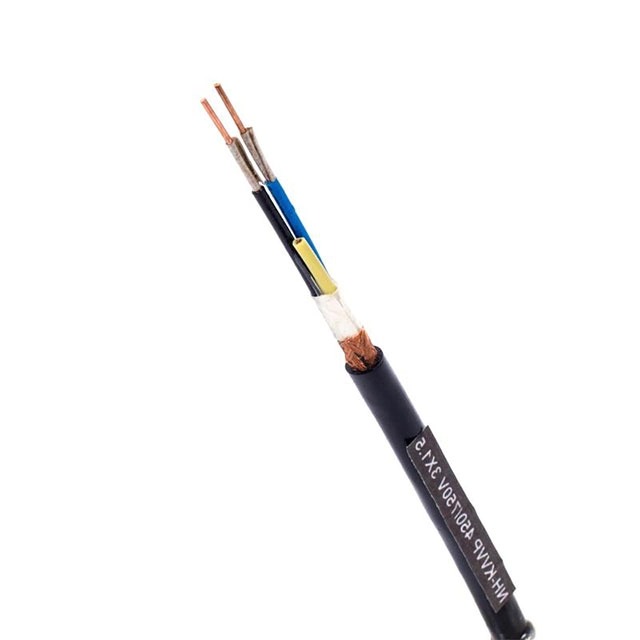

Construction Features

Control cables usually consist of copper conductors, insulation layers, and shielding to minimize electromagnetic interference (EMI). Hybrid cables, however, may include different cable types within one jacket: for instance, combining copper power cores with optical fibers for data. This complexity makes hybrid cables more versatile but also more expensive to manufacture.

Application in Energy Systems

In energy facilities, control cables are commonly used for relay connections, monitoring devices, and control circuits. Hybrid cables are better suited for smart grids, wind farms, and offshore platforms, where data transmission and power delivery must coexist in harsh environments.

Design Considerations in Control Cable Construction

A closer look at control cable design explains why they differ from hybrid cables in performance and application.

Conductor Material and Size

Most control cables use copper conductors due to their high conductivity and flexibility. Depending on voltage and current requirements, conductor sizes vary from small signal lines to larger cores for auxiliary power. Hybrid cables may include mixed conductors—copper for power and glass fibers for optical data—making them less standardized.

Shielding and Protection

Control cables are often shielded with foil, braid, or a combination to protect signals from EMI, particularly in high-voltage environments like substations. Hybrid cables may incorporate both shielded communication pairs and armored power cores within one sheath, which adds complexity but enhances performance in data-heavy environments.

Insulation and Outer Sheath

The insulation of control cables typically uses PVC, XLPE, or PE, depending on environmental resistance needs. Hybrid cables often employ specialized sheathing that accommodates both electrical and optical performance, making them more resistant to moisture, oil, and mechanical stress.

Functional Advantages of Control Cables in Energy Applications

While hybrid cables offer versatility, control cable remains indispensable in many energy sector systems.

Reliability in Critical Systems

Control cables are widely trusted in power plants and grid substations due to their predictable behavior and compliance with international standards. Engineers value their high signal accuracy, which is vital for relay systems and automated shutdown protocols.

Cost-Effectiveness

Compared to hybrid cables, control cables are less expensive to produce and install. They are available in standard configurations, making procurement easier for energy companies. Hybrid cables, while powerful, often require custom manufacturing, which increases costs.

Simplified Maintenance

Control cables have a straightforward design, which makes fault detection and repair simpler. In contrast, hybrid cables may require specialized tools or technicians to service both the power and optical components.

Where Hybrid Cables Excel Over Control Cables

Despite the reliability of control cables, hybrid cables provide unique advantages in advanced energy systems.

Integration of Power and Communication

Hybrid cables eliminate the need to run separate lines for electricity and data. This is particularly useful in wind turbines or offshore platforms, where space and installation efficiency matter.

Reduced Installation Complexity

By combining different cable functions into one sheath, hybrid cables cut down on installation time and material use. This can significantly lower project costs in large-scale renewable energy farms.

Enhanced Data Transmission

Hybrid cables often include fiber optic elements, allowing real-time data monitoring. In modern energy grids, this supports smart grid operations and predictive maintenance strategies.

Comparative Overview: Control Cable vs. Hybrid Cable

| Feature / Aspect | Control Cable | Hybrid Cable |

| Primary Purpose | Signal transmission and control | Combined power + data transmission |

| Construction | Copper conductors, shielding, insulation | Mixed (copper + optical fiber or others) |

| Cost | Lower, standardized | Higher, often custom-made |

| Applications | Substations, automation, monitoring | Smart grids, renewable energy, offshore |

| Maintenance | Easier and cheaper | More complex, requires expertise |

Selecting the Right Cable for Energy Projects

When choosing between a control cable and a hybrid cable, project requirements should dictate the decision.

Project Environment

For stable, land-based facilities, control cables are sufficient and cost-effective. For harsh, remote, or space-limited environments like offshore wind farms, hybrid cables often provide better value.

Budget and Long-Term Costs

Initial costs are lower for control cables, but hybrid cables can reduce infrastructure duplication and long-term installation expenses. Decision-makers should calculate total cost of ownership (TCO) before choosing.

Future-Proofing Energy Systems

As the power sector moves toward digitalization and smart grids, hybrid cables become increasingly relevant. However, for many traditional applications, control cables will continue to be the preferred option.

Practical Use Cases in the Power and Energy Industry

Control Cable in Substations

Control cables are widely used for relay protection, switchgear control, and signal monitoring. Their predictable performance ensures that energy distribution remains stable and safe.

Hybrid Cables in Wind Farms

Hybrid cables are the backbone of modern wind energy projects, where they can carry both the generated power and fiber optic data for performance monitoring.

Offshore Energy Platforms

Hybrid cables are particularly valuable in offshore platforms, where installation space is limited and reliability under harsh conditions is critical.

Extended Comparison Table: Technical Features

| Technical Feature | Control Cable | Hybrid Cable |

| Voltage Rating | Typically up to 1kV | Can include low to medium voltage |

| Data Capability | Limited to control signals | High-speed data via fiber optics |

| Flexibility | High for simple installations | Moderate due to mixed construction |

| Durability | Resistant to EMI, chemicals | Resistant to harsh weather & pressure |

| Common Standards | IEC 60227, IEC 60502 | Project-specific or custom standards |

Conclusion

Hybrid cables and control cables are not competitors but complementary solutions within the energy sector. Control cables remain the backbone of power system control, valued for their reliability, affordability, and simplicity. Hybrid cables, meanwhile, represent the future of integrated energy systems—streamlining installation, enabling smart monitoring, and supporting renewable energy projects.

Choosing the right cable depends on the project’s environment, cost constraints, and data requirements. By understanding the differences, energy professionals can make informed decisions that balance performance, safety, and long-term efficiency.

FAQ

1. What is the main purpose of a control cable?

A control cable is designed to transmit signals for monitoring, controlling, and automation in electrical systems, especially in power plants and substations.

2. Why are hybrid cables more expensive than control cables?

Hybrid cables combine multiple functions—often power and data—into one sheath, requiring advanced materials and manufacturing processes, which increase their cost.

3. Can control cables be replaced by hybrid cables?

Not entirely. While hybrid cables offer integration benefits, control cables remain essential for many standardized applications due to cost-effectiveness and simplicity.

4. Where are hybrid cables most beneficial?

Hybrid cables are most beneficial in renewable energy projects (such as wind farms) and offshore installations, where both power and data need to be transmitted simultaneously in limited space.

5. Which cable type is better for smart grid systems?

Hybrid cables are more suitable for smart grids because they support both electricity transmission and high-speed data communication for real-time monitoring.